What Are the Most Common Applications of Plastic Injection Molding?

Plastic injection molding has grown significantly in popularity during the past few years because it is a cost-effective, fast, and durable way to produce components for a variety of systems. As technology has progressed, the applications of plastic injection molding have grown as well. Take a look at some of the most common industries in which plastic injection molding plays a pivotal role.

The Building and Construction Industry

One of the most common applications of plastic injection molding is in the building and construction industry. Plastic injection molding is suitable for this field because it has incredible durability when exposed to the elements, is energy efficient, incredibly light, and has high material stability. Manufacturing professionals can use plastic injection molding to produce a wide variety of construction products and parts. These include accessories, fasteners, hand tools, and even components for power tools.

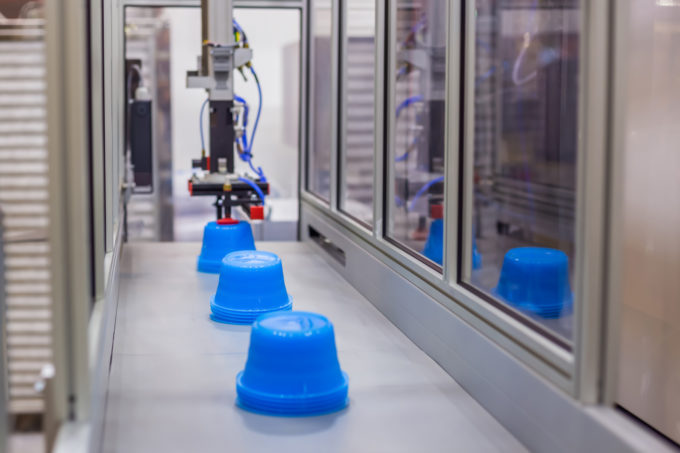

The Food and Beverage Industry

Plastic injection molding also plays a key role in the food and beverage industry. As companies strive to meet the regulations of the FDA, plastic injection molding is beneficial. Plastic injection molded parts are made with food-grade materials, meaning they are free from BPAs and meet all GMA compliance standards. Materials can also be made with UV resistance, chemical resistance, and durability in the autoclave, which is important for sterilizing tools. Plastic injection molding can be used for food and beverage containers, beverage filters, and conveyor systems.

The Automotive Industry

There’s an increasing demand for lightweight components that do not sacrifice durability in the automotive industry. This is perfect for plastic injection molding. Auto manufacturers can use plastic injection molding to produce small parts that are necessary for the advanced features of cars. Furthermore, plastic injection molding is perfect for situations where parts need to stand up to the elements, which includes cars that have to drive in the rain, sun, and snow. Plastic injection molding can also help auto manufacturers reduce their expenses, which creates savings that can be passed on to the consumer.

The Toy Industry

The toy industry has changed significantly during the past few years, and toymakers have increasingly turned to plastic injection molding for efficient, rapid production of bulk orders. Furthermore, plastic injection molding is also perfect for video game manufacturers. Plastic injection molding gives manufacturing companies the ability to produce small parts with incredible attention to detail, which is important for producing toys and video games. As technology continues to progress, plastic injection molding gives toy manufacturers the ability to produce more toys in a shorter amount of time with a greater degree of accuracy.

The Medical Industry

Plastic injection molding plays a pivotal role in the medical field as well. Engineering grade and food gray plastic resins are perfect for the healthcare industry, as these parts can be resistant to extreme temperatures while also being given the high tensile strength that is required in the medical field. Medical components can also be made lightweight, which makes them easier to move from patient to patient. With the ability to rapidly fulfill large orders, the medical field has become reliant on plastic injection molding to meet their needs.

Rely on Special Tool & Engineering, Inc. for Plastic Injection Molding

These are just a few of the most common industries in which plastic injection molding is used. If you want to get the most out of plastic injection molding, you need to work with a professional who can help you. At Special Tool & Engineering, Inc., we have a tremendous amount of experience working with professionals in a wide variety of fields. We can customize our plastic injection molding services to meet your needs. Contact us today to learn more about how we can assist you.